Our specialty is to provide unique machines designed to operate in all environments.

Our unique expertise

OPTIM Technologies has developed cutting-edge know-how based on 20 years of experience in the design and manufacture of special machines for the demanding Nuclear, Petrochemical and Naval Defense markets.

Indeed, for all these years OPTIM Technologies has provided technical and innovative solutions to meet the most complex challenges encountered by its customers and for which “ready-to-use” solutions do not exist, whether to intervene in sea at a depth of 4000 meters, in the heart of a nuclear installation, in a refinery, a workshop or a shipyard.

Our Business

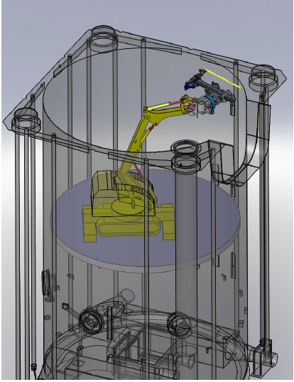

Optim Technologies imagines, designs and manufactures special machines meeting the specific needs of its customers and adapted to the most demanding environments in the nuclear, petrochemical and naval defense sectors.

To do this, OPTIM Technologies is notably required to realize:

- Machining, drilling or boring machines operating in difficult environments

- Remote-controlled machines

- Dismantling machines

- Control machines operating in hostile environments

A unique expertise

A unique offer

A smart production

OUR MARKETS

Nuclear industry

- Tele-operated machines

- Dismantling

- Sampling machine

- Waste box cutting

- Test bench

- Welding assistance

Oil & Gaz industry

- R&D and prototyping

- Machining or grinding on site

- Pipe chamfering and cutting machines

- Inspection machines

- Remote-controlled long-distance in-pipe machines 100m 500m 1000m

- Technical assistance and training

Navale industry

- Submarine hull machining centres

- Drilling, milling, boring and facing

- Large boring bars

- Pipe cutting and chamfering machines

- Automation

The innovative OPTIM Technologies designs have provided answers to demanding situations where “standard” solutions do not exist. At sea, at a depth of 4,000 meters, in the heart of a nuclear installation, in a refinery, a workshop or a shipyard, OPTIM Technologies will design and manufacture on site machines bespoke machine tools, specially adapted to the most demanding environments.

OPTIM Technologies has a unique experience, worldwide, in conception, manufacturing of special machines in hostile environments in the petrochemical, power generation, nuclear, offshore, shipbuilding, industrial maintenance and installation.

OPTIM Technologies has created and development team capable of responding quickly to customers whose needs are often urgent.

Working closely with the client’s design team, OPTIM Technologies brings its vast experience and expertise to the development of innovative solutions to tackle “impossible” challenges. Using the most up-to-date design capabilities and materials, results are achieved by integration with the customer’s engineering team and ongoing monitoring in the initial stages of validation. All machine design projects are undertaken using the best 3D solid modeling and calculation softwares .

First, the initial designs are presented to the customer to validate the integrity of the design. Manufacturing drawings are produced from the approved design and the machine is produced for initial proof.

OPTIM Technologies will assist with the initial tests and will implement, if necessary, any modification or improvement required by the customer, or deemed advantageous by OPTIM Technologies, thanks to this first practical experience.

OPTIM Technologies has developed relationships with selected machining specialists to ensure results are achieved on all component materials.

Our experience, acquired in various sectors of activity, ensures you a solid expertise to design and manufacture the machines that meet your technical problems.

quality and safety

Company certified ISO 9001:2015 / ISO 45001:2018